Your LED electronics development as a whole

Do you have an innovative idea and are you looking for a competent, reliable partner in LED electronics development for your product/project? If many years of experience and rapid implementation are important to you and you also value efficient LED technologies, then you’ve come to the right place. We offer a holistic concept for your projects/products. Let us convince you with an excerpt from our services:

Our top priority is to bring your product to market in the shortest possible time!

Starting with your idea, we support you with our know-how in all phases of your project

(from concept development, during development, through to series production).

Our references

We are very proud of our references. However, we do not publish these not published. Discretion is important to us, i.e. our customers remain incognito.

- In other words, it is up to the customer to present their project, not us

- Your project - your data - your fame

- We don't just pay lip service to NDAs, we live them through and through

Hardware that works is one thing. Hardware that is resistant to interference, robust and yet inexpensive is another.

- With HW, nothing beats experience, of which we have plenty

- Analog, digital and power electronics

- Close coordination with SW development + production. Partly the same person, so there are no interface losses

- Prototype production + EMC equipment as a time booster directly in-house

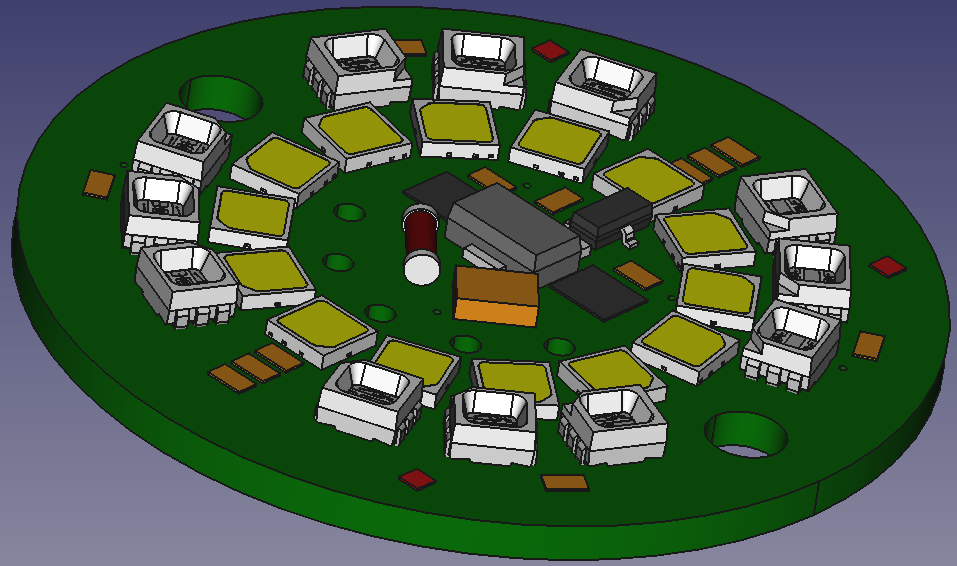

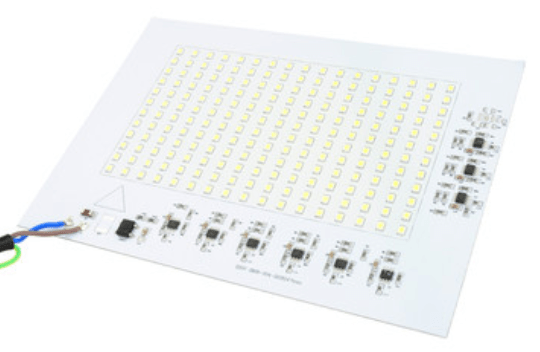

Layout development

Complex PCBs can be developed using 3D-supported layout design. The layout is a central element in LED electronics development in particular. In addition to the electrical connections, the focus is primarily on thermal design requirements. In addition, the efficiency and the design of the cooling can be optimized considerably!

- Metal core board

- Rigid-flex boards

- Flex boards

Microprocessor-based systems extend the functionality of the hardware. What’s more, it can be expanded even if the product is already on the market!

- Different bootloaders programmed

- Modular code to save development time

- All SW developers are also trained HW developers: no interface losses

- Very extensive in-house interface experience (DMX, RDM, DALI, Push-Dim, I²C,...)

The basis for issuing the declaration of conformity is the EMC.

- Continuous line bundle measurements

- Measurement with the near-field probe e.g. switching regulator

- Line measurements with coupling clamp

- Surge burst measurements

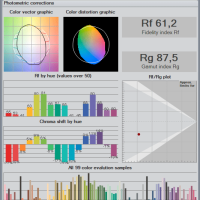

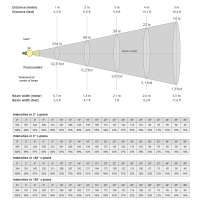

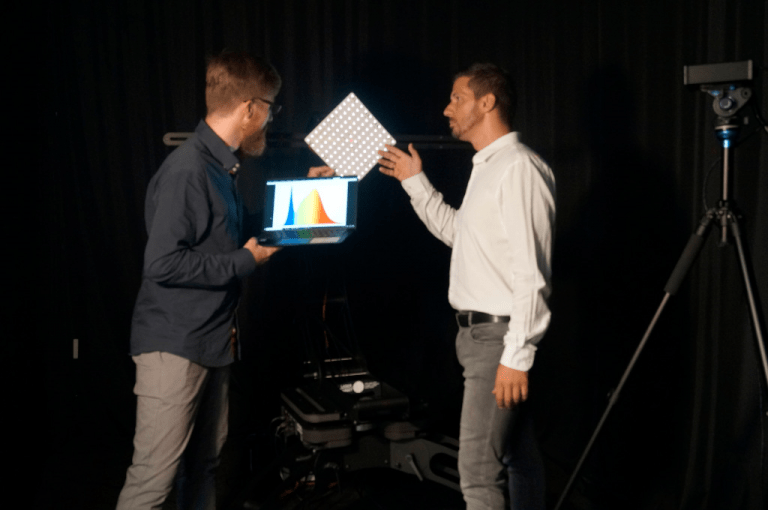

An important tool for sustainable LED electronics development and production

- Create facts > Spectral values, UGR value, CRI and much more

- Adaptation of optics, radiation characteristics

- Recurring measurements for quality assurance

- Empirical measurements of various superstructures

- Optimization of the efficiency of the Lightengine

- 2D/3D CAD design

- Wide range of suitable materials (mechanical, thermal, electrical, ...)

- Cost-optimized production as a design criterion

- Design meets functional principles

Beyond "LED electronics development"

Manufacturing

Did you know that, in addition to reflow ovens, we also have various (de)soldering stations and a high-precision 3D liquid printer in-house? Nevertheless, our SMD placement machine remains the highlight of our production!

Know-How

For any form of LED electronics development as a whole, one thing is indispensable: knowledge! From time to time we will also expand our article database here and put it online